ENGINEST

TEL:+33(3) 83551299

FAX:+33(3) 83970552

E-Mail:info@enginest.com

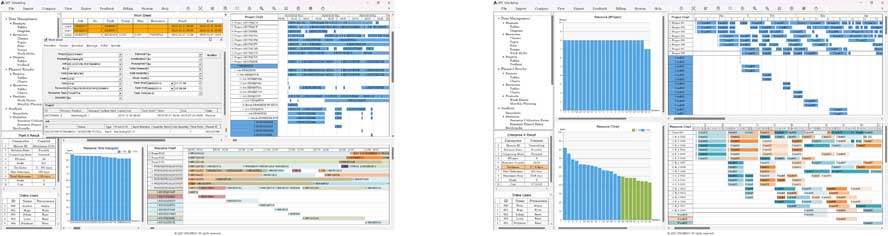

APS (Advanced Planning and Scheduling) involves planning and scheduling tasks on resources, at an operational level, to accomplish the required jobs in efficiently employing limited resources. In the manufacturing industry, APS is known to be the technical bottleneck for a manufacturing execution system.

To this date, the APS running in POEM is capable of solving large-scale industrial problems subject to hundreds of kinds of constraints, also capable of real-time simulation and interactive/emergency re-scheduling. The general-purpose APS is designed at a high-level of abstraction so as to meet user requirements as wide as possible, available for fields as various as production scheduling, command/control, and project management. Moreover, this open APS is easy to be integrated with peripheral systems such as MES.

Constraints

Constraints

process structure of a product,

process structure of a product,

temporal constraints over the orders,

temporal constraints over the orders,

structured resource requirements for tasks,

structured resource requirements for tasks,

coordination constraints for tasks with multiple resources,

coordination constraints for tasks with multiple resources,

distance constraints between different tasks over mobile resources,

distance constraints between different tasks over mobile resources,

duration, earliest start and latest end of a task,

duration, earliest start and latest end of a task,

execution order of tasks over resources ,

execution order of tasks over resources ,

parallel and/or sequential capacities of resources,

parallel and/or sequential capacities of resources,

allocation and mobilization of resources over work sites,

allocation and mobilization of resources over work sites,

mobility of resources,

mobility of resources,

calendars (availability) of resources,

calendars (availability) of resources,

daily work slots,

daily work slots,

resource group (work team) organization ,

resource group (work team) organization ,

division in batch of a task,

division in batch of a task,

division in quantity of a task over resources so as to minimize the duration,

division in quantity of a task over resources so as to minimize the duration,

coordination of the cooperation of different job-shops, …

coordination of the cooperation of different job-shops, …

Objectives:

Objectives:

Minimize the delay of delivery

Minimize the delay of delivery

Minimize the make-span

Minimize the make-span

Minimize the number of resources, ...

Minimize the number of resources, ...

Features

Features

Involving logistics planning for AGVs (Automated Guided Vehicles),

Involving logistics planning for AGVs (Automated Guided Vehicles),

Supporting automated manufacturing with robots by taking into account coordination constraints for robots, machines and AGVs.

Supporting automated manufacturing with robots by taking into account coordination constraints for robots, machines and AGVs.

1 Allée de l'Alzette, 54500 Vandœuvre-lès-Nancy Telephone: +33 (3) 83 55 12 99 Email: info@enginest.com

© 2023 ENGINEST Legal terms